interestingengineering.com

Oil Company Recycles CO2 by Curing Concrete with It

The construction industry is a major contributor to carbon emissions, but this new method could help trap carbon "on-site".

Science & Tech

As the transportation industry is slowly moving away from fossil fuels, the demand for green alternatives has risen. But when it comes to carbon emissions, there is another elephant in the room that needs addressing: the construction industry.

The construction industry is another major contributor of carbon emissions released into the atmosphere, and a Saudi oil company, Aramco, believes that trapping carbon dioxide in concrete could prevent its release without disrupting the construction industry.

The 2019 International Energy Agency report on buildings and constructions estimates that the building and construction sector accounts for 39 percent of global carbon emissions, of which 11 percent accounted for the production of building materials such as steel, glass, and cement. While industries are using carbon capture methods to prevent the immediate release of carbon dioxide into the atmosphere, carbon sequestration methods are also highly questionable and resource-intensive.

In the conventional construction process, the cement mixes with water and begins to harden. Builders try and maintain the right temperature and moisture levels for periods of up to 28 days to ensure that the concrete reaches its maximum strength. There are many methods already in use to 'cure' concrete in a manner where it is more durable and crack resistant.

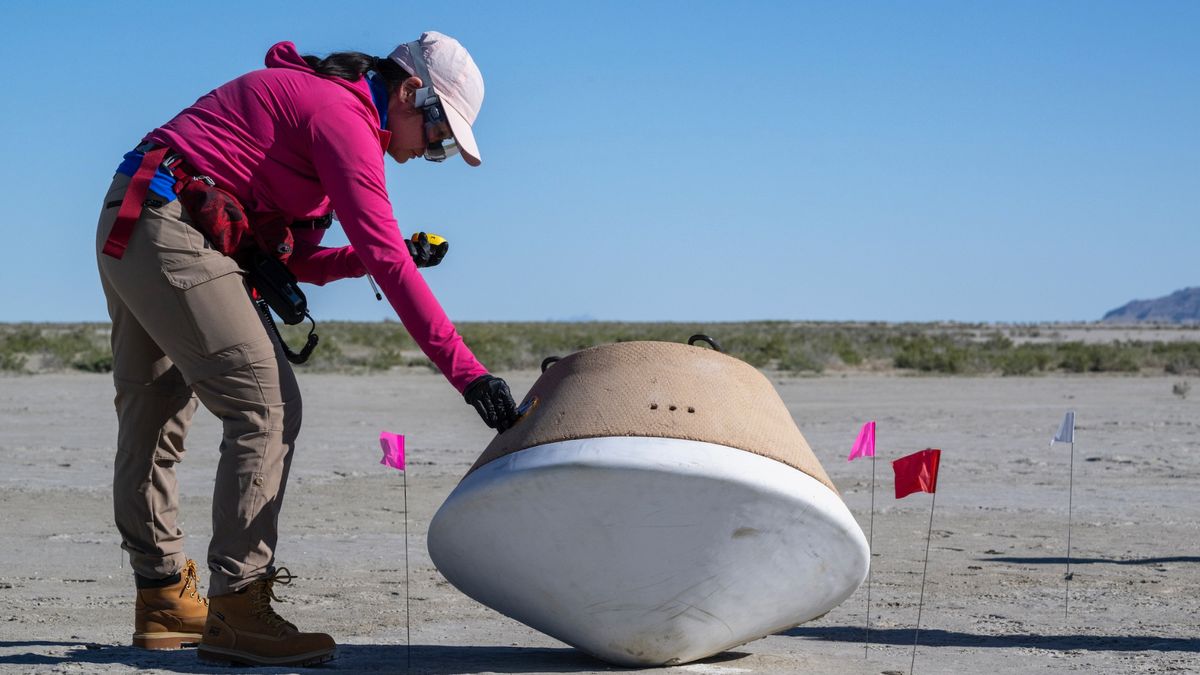

The method suggested by Aramco modifies one such method of steaming and can trap as much as 20 percent of carbon dioxide in the concrete. Developed in collaboration with researchers at the Korea Advanced Institute of Science and Technology (KAIST), the team focused on using their method for precast concrete, which offers a more controlled environment, reduces potential errors, and is rapidly becoming the preferred method for construction.

Using carbon dioxide in the curing process allows concrete to harden faster: the new process took just three days when compared with the previous 28-day waiting time. The team also verified the strength of the concrete following the treatment and found that it passed industry benchmarks with ease.

The company estimates that if the precast industry switched to using carbon dioxide for curing, they could annually recycle 246 million tons of carbon dioxide which is the equivalent of emissions from 53 million cars. This easy-to-deploy method could be deployed to trap emissions from cement production itself and help in fighting climate change. The company is now working on methods to increase the amount of carbon dioxide that can be trapped during the curing process.